How to Find Direct Labor Hours Per Unit

Note that it is an average and actual unit labor costs may be above and below the average. The labor routing includes normal inefficiencies that are to be expected during the production process such as downtime for machine setups break time and an allocation for time.

Direct Labor Standard Cost And Variances Accountingcoach

If it takes one person 2 hours of work to make a single widget then the labor cost is 46 per.

. To make a standard labor cost card for each unit write down your calculations in detail. In the example divide 200 by 800 to calculate 025 hours per unit or 15 minutes per unit. On average 500 pieces eg.

As an example if your employees produced 800 units in the 200 total man-hours during the week divide 800 by 200 to calculate 4 units per man-hour. Divide the overhead costs by the number of billable hours. On the basis of time cards the departmental payroll or wage sheets are prepared.

Multiply your average labor hours per unit by the average wage rate per hour. Door handles are produced a day. Calculate the cost per widget.

Manufacturing Engineering provided the per unit labor standard for Product XYZ which was set at 0130 hours per unit which when multiplied by the number of starts17496indicating a need for 227 hours of direct labor build time to complete this requirement. Once you have the total cost the direct labor rate is calculated by dividing that dollar amount by the total hours of labor calculated earlier. 10 x 8 500 80 500 016 h 96 minutes Hence it takes 016 man-hours per unit to produce a piece of product for such a low figure it is assumed that machinery is in place to produce the product in mass at a fast rate.

There are 10 workers working in the manufactory working 8 hours a day. 6 Providing internal check system in payment of wages. Use direct labor costs to guide your decisions.

That way if machine downtime increases or average wages. The standard labor cost per unit of Modex company is therefore 585 as computed below. An example of how being aware of direct labor cost can save over 50 000 just think of the savings when you monitor the other product cost listed in TDC metrics.

The standard hours per unit is derived from the labor routing which is a compilation of the normal amount of time expected to be required to manufacture a unit. Add that to the 20 hourly pay and you have 23 per hour in direct labor costs. This is your average labor cost per unit.

Preparation of Pay Roll. 5 Ascertaining overtime and idle time wages. Traditionally in a job order cost system and process cost system overhead is allocated to a job or function based on direct labor hours machine hours or direct labor dollars.

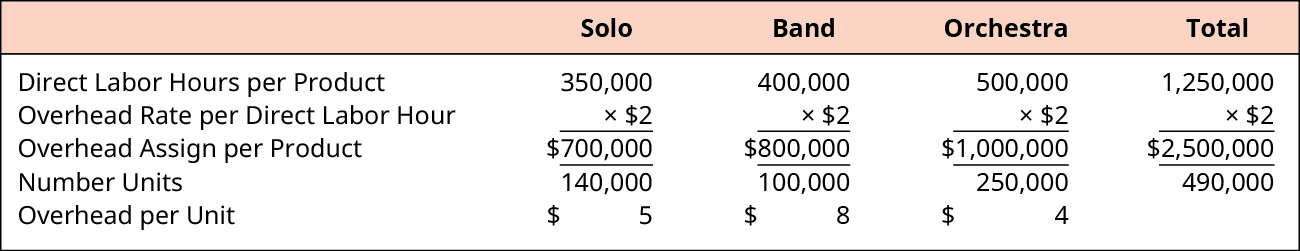

Calculating the Plantwide Overhead Rate To calculate the plantwide overhead rate first divide total overhead by the number of direct labor hours used to find the overhead per labor hour. 60 units per hour. When using ABC the total cost of each activity pool is divided by the total number of units of the activity to determine the cost per unit.

Since the standard direct labor rate is 10 per hour the labor efficiency variance is 2000 computed as follows. Compute the total overheads of the business. Multiply 2250 by 08 and you have a per-unit direct labor cost of 1800.

Use the following data to find the direct labor efficiency variance if the company produced 3500 units during the period. Labor efficiency variance Actual hours worked Standard hours allowed x Standard rate 22200 actual DL hours x 22000 standard DL hours x 10 per hour 200 hours x 10 2000 unfavorable variance. To calculate the overhead rate per employee follow the steps below.

Cost per unit and units per hour. Calculate the labor cost which includes not just the weekly or hourly pay but also health benefits vacation pay pension and retirement benefits paid by the employer. Determine additional labor costs.

Cost per unit at that stage in production. The direct labor standards indicated 24 hours at a standard wage of 20 per hour totalling 4800 per finished unit. 18 325hours 585.

Divide one hour by the number of times the operation can beperformed in that hour. Actual units manufactured were 9000 units at 25 hours. Determine costs for hours worked.

4 Ascertaining the total hours of each cost centre to calculate labour cost and rate per hour for control purpose. Like other cost elements direct materials and manufacturing overhead the standard labor cost per unit is written on the. Calculate direct labor cost.

How to calculate direct labor cost step-by-step. Direct labor standard 4 hrs. Invert this calculation to determine the average production time per unit.

In our example the standard time to complete one unit is 325 hours and the standard labor cost per hour is 18. The labor cost formula to calculate direct labor cost per unit is the standard cost of one hour of labor multiplied by the number of hours needed to produce one unit. Wage 21 per hour totalling 5250.

To find machine hours per unit divide the total number of hours that machinery is operated by the number of units produced. How do you calculate standard labor cost per unit. 160 00167 standardhourCost of the.

We go through the same process for all 5 products for the entire year. Divide 120 by 40 giving 3 per hour. Tips Total machine hours can be calculated on a daily weekly monthly or even annual basis.

Per unit labor hours can be calculated by dividing the total labor hours used to manufacture each product by the number of units manufactured. 12hr Actual hours worked Actual rate per hour 48 per unit 12250 1250 - Ο 21000 favorable.

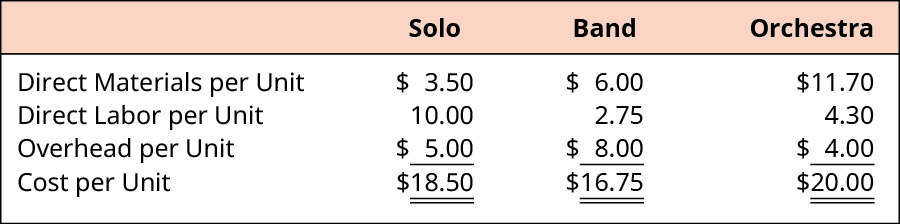

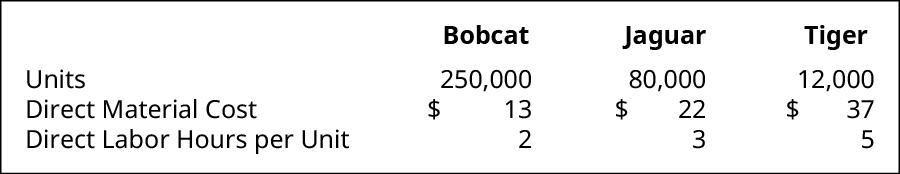

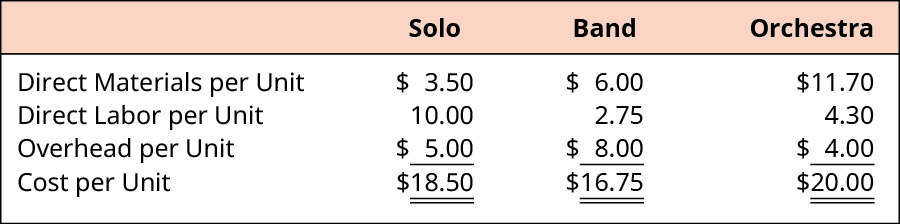

Calculate Predetermined Overhead And Total Cost Under The Traditional Allocation Method Principles Of Accounting Volume 2 Managerial Accounting

Calculate Predetermined Overhead And Total Cost Under The Traditional Allocation Method Principles Of Accounting Volume 2 Managerial Accounting

Calculate Predetermined Overhead And Total Cost Under The Traditional Allocation Method Principles Of Accounting Volume 2 Managerial Accounting

0 Response to "How to Find Direct Labor Hours Per Unit"

Post a Comment